Hello, my name is KS

Everything happens for a reason

Dig deeper now & less issue later

Select the right tool for the right job

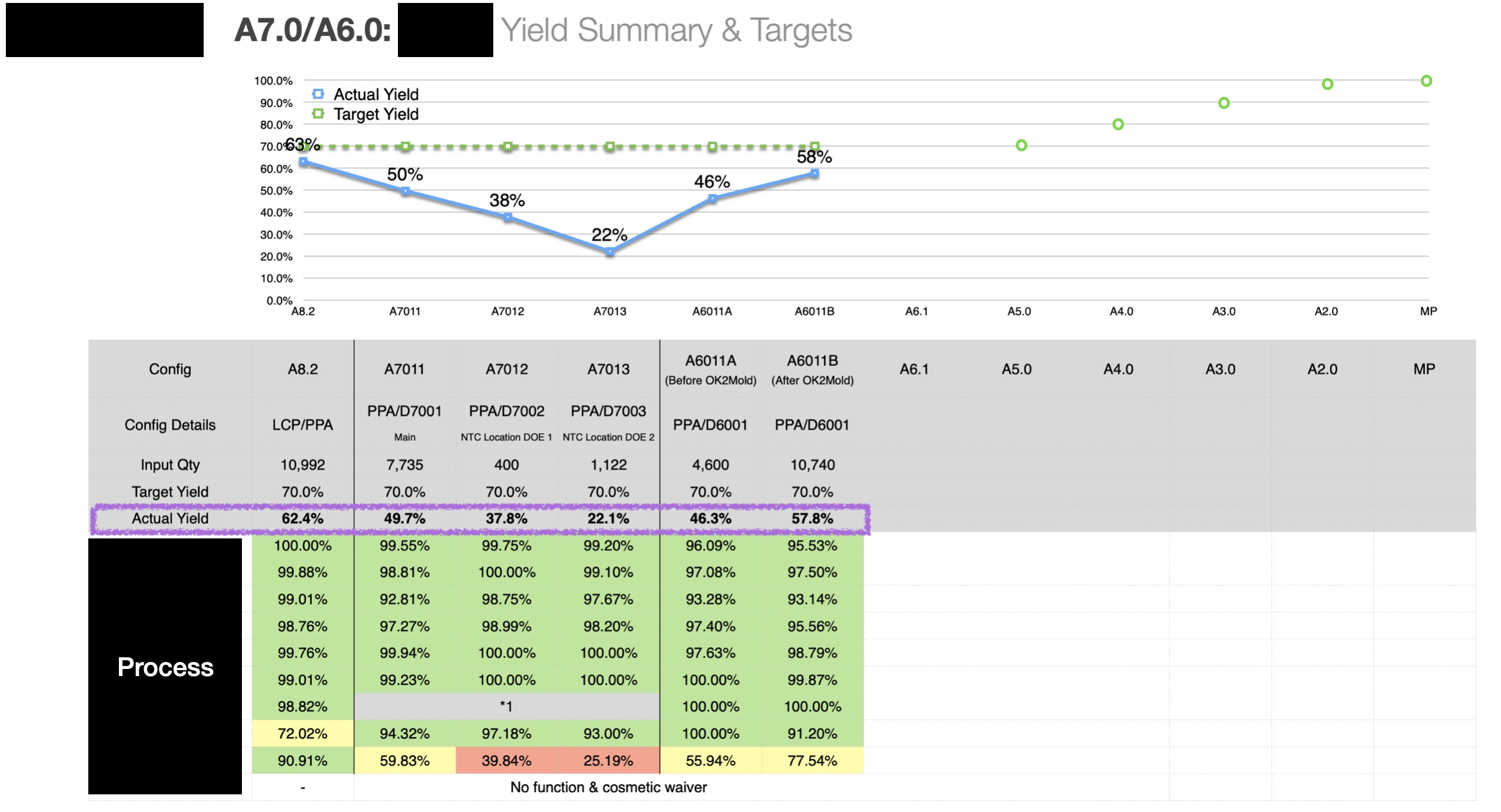

Yield Improvement

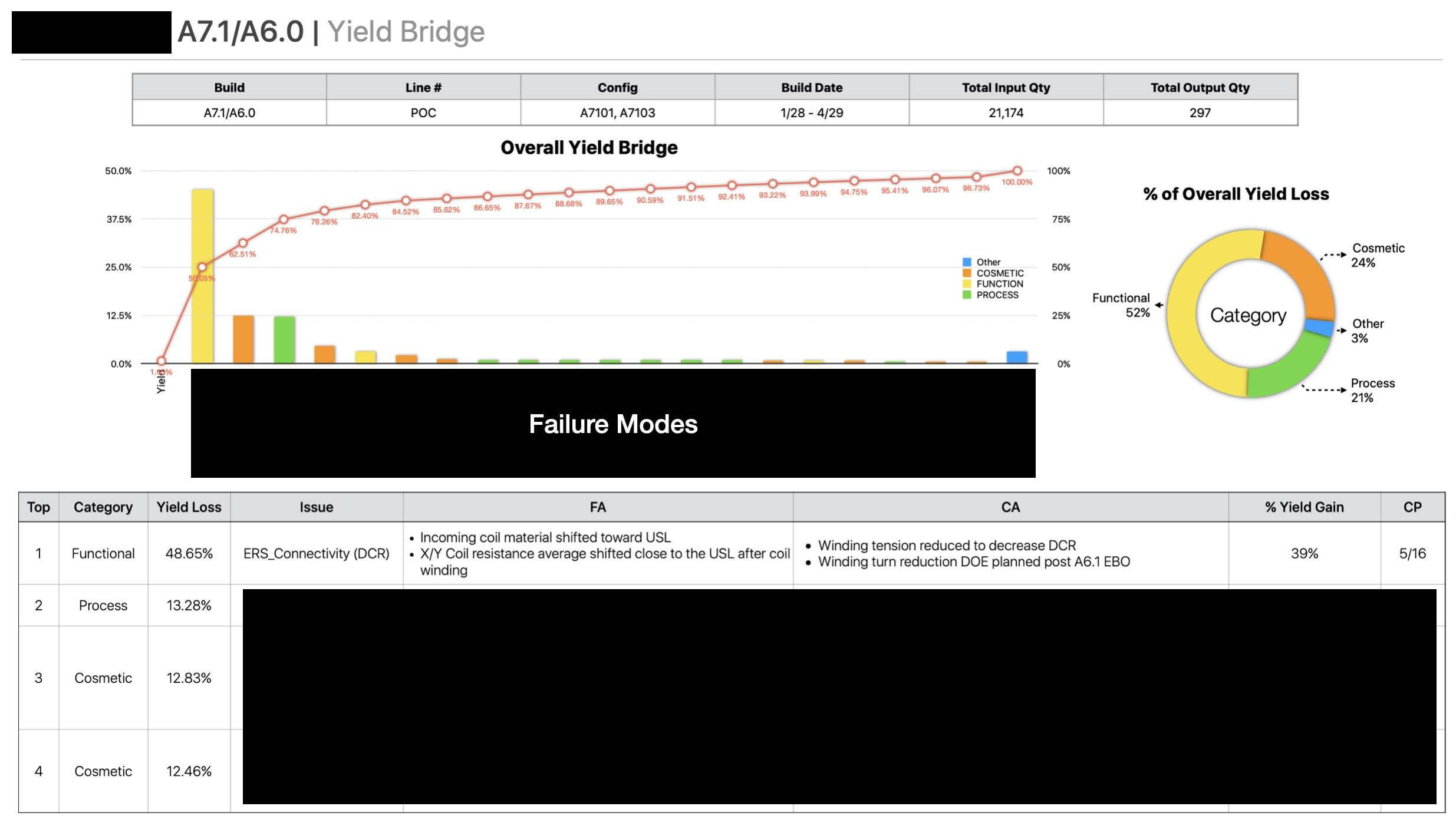

During new product development stage, yield should always be concerned, as it will impact the product cost & manufactureablity.

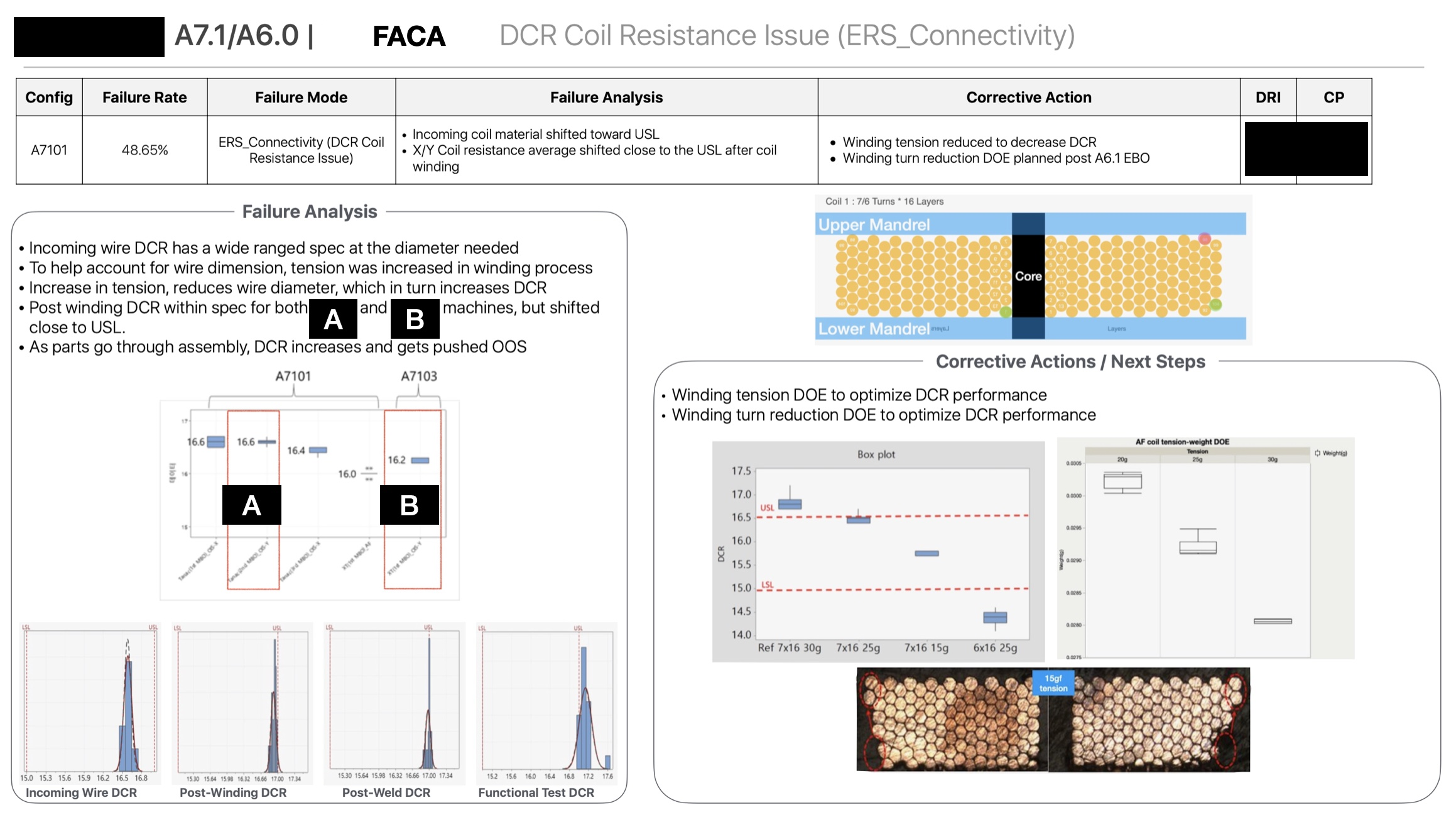

To reduce yield loss, Failure Analysis & Corrective Action (FACA) is a routine task from day1.

FA require team deep diving into design, material & process perspective, plus choosing the right analysis tool for root cause finding.

CA determined after multiple engineering check, can be design simulation Finite Element Analysis (FEA), Tolerance Analsysis (TA) & process DOE, continuous tuning until perfect.

Failure Analysis Tool

Optical Measuring Machine

Using high resolution AF camera + flexible lighting for precise mechnical dimension measurement.

3D Surface Profiler

Using white light inteferometry or/and confocal scanning method to measure the 3D structure or surface profile, generate depth map.

High Power Microscope

Using high magnification optics system to allow manual visual inspection.

Confocal Scanning Acoustic Microscopy (CSAM)

Using ultrasound wave, pulses of different frequencies are used to penetrate material to examine interiors for voids or delamination.

Scanning Electron Microscope - Energy Disperse Xray(SEM-EDX)

SEM: Electron beam shooted and get back info like BackScatterEd (atomic # delta) & 2nd Electron (topographic), generate fine texture gray scale image.

EDX: Consist of Silicon-Drift Detectors(SDD) to measure the X ray photon energy, providing spectra with peak (X=number of count, y=energy). This is used to analyse the composition of the material.

Fourier Transform InfraRed Spectrocopy (FTIR)

Using IR and measure the infrared absorption or reflectance spectrum to determine vibrational frequencies, which provides information on chemical structure and bonding. Good for organic and polymer material analysis.

Water Contact Angle (WCA)

Using water droplet on a surface, measure the angle form between droplet and surface, resulting surface wettability & hydrophobicity. Check cleanliness of a surface.

Computed Tomography Scan

Using X-rays beams collimated to create a line, then translated across the part and data is collected by the detector. The data is then reconstructed to create a 3-D image. Good to check the internal component dimension and assembly flaw.

X-ray

Using Xray (high energy electromagnetic radiation, 10nm-10pm) to inspect inner component crack/damage.

Differential Scanning Calorimetry (DSC)

DSC measures heat flow of a sample over a temperature range, help to determine glass transition, cystalisation & melting temperature, used to analyse if an applied epoxy is fully cured.

Trioptics Optics Tester

Using multiple colimator lens vision or chart, to measure optical characteristic like MTF, DFOV, FL... of an optics product or lens.

High Speed Camera

HSC (high throughput, high frame rate) help to capture video for extreme fast/fine machine mechanism, help to optimise machine sequence/delay.

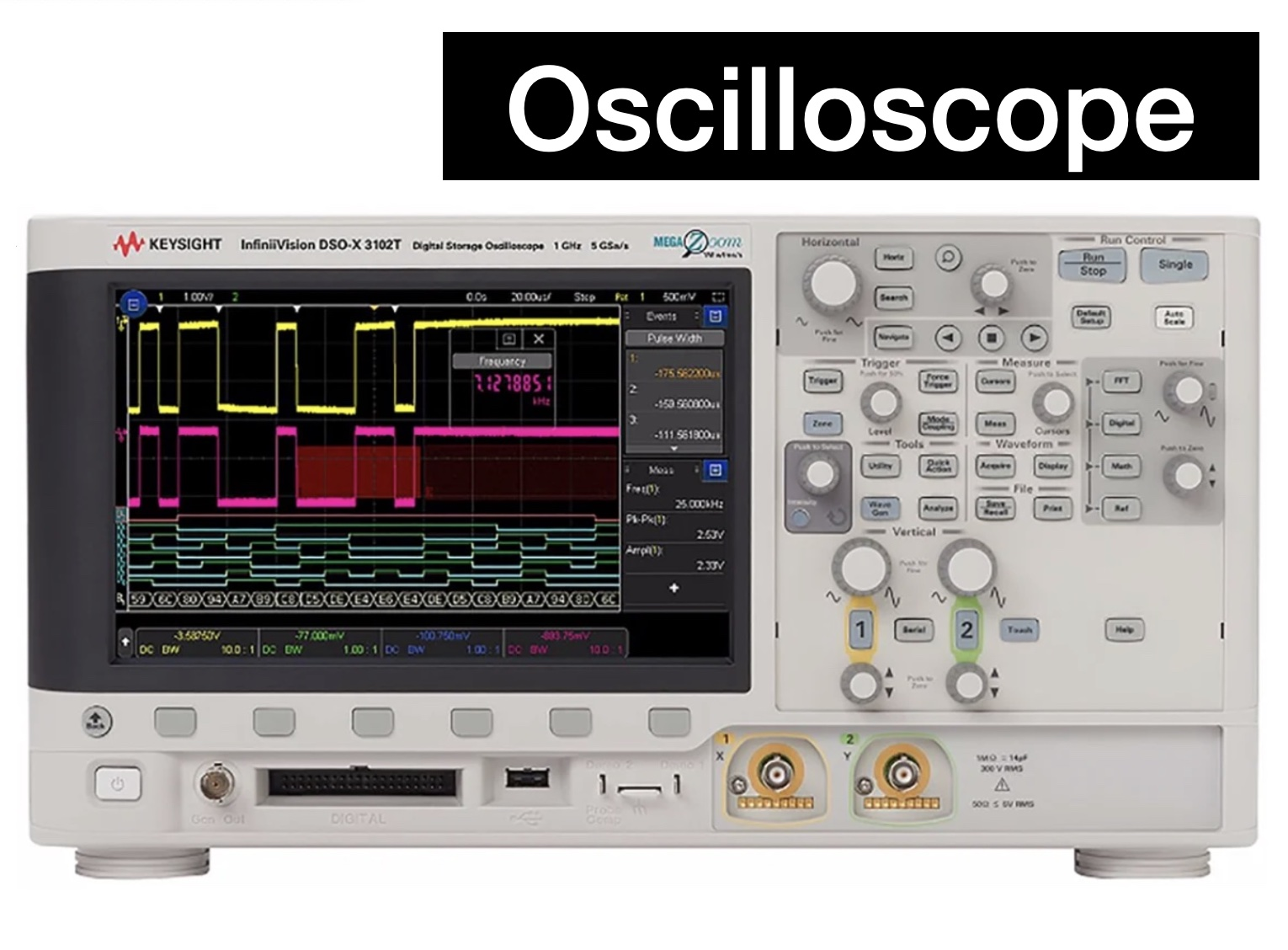

Oscilloscope

It help to capture information on electrical signals for debugging, analysis, or characterization. The displayed waveform can then be analyzed for properties such as amplitude, frequency, rise time, time interval, distortion, and others

Curve Tracer

It apply a swept (automatically continuously varying with time) voltage to two terminals of the device under test and measure the amount of current that the device permits to flow at each voltage(I-V curve), used to detect if circuit broken.

Time Domain Reflectometry (TDR)

It help to determine the characteristics of electrical lines by observing reflected pulses, used to detect if circuit intermittent/broken.

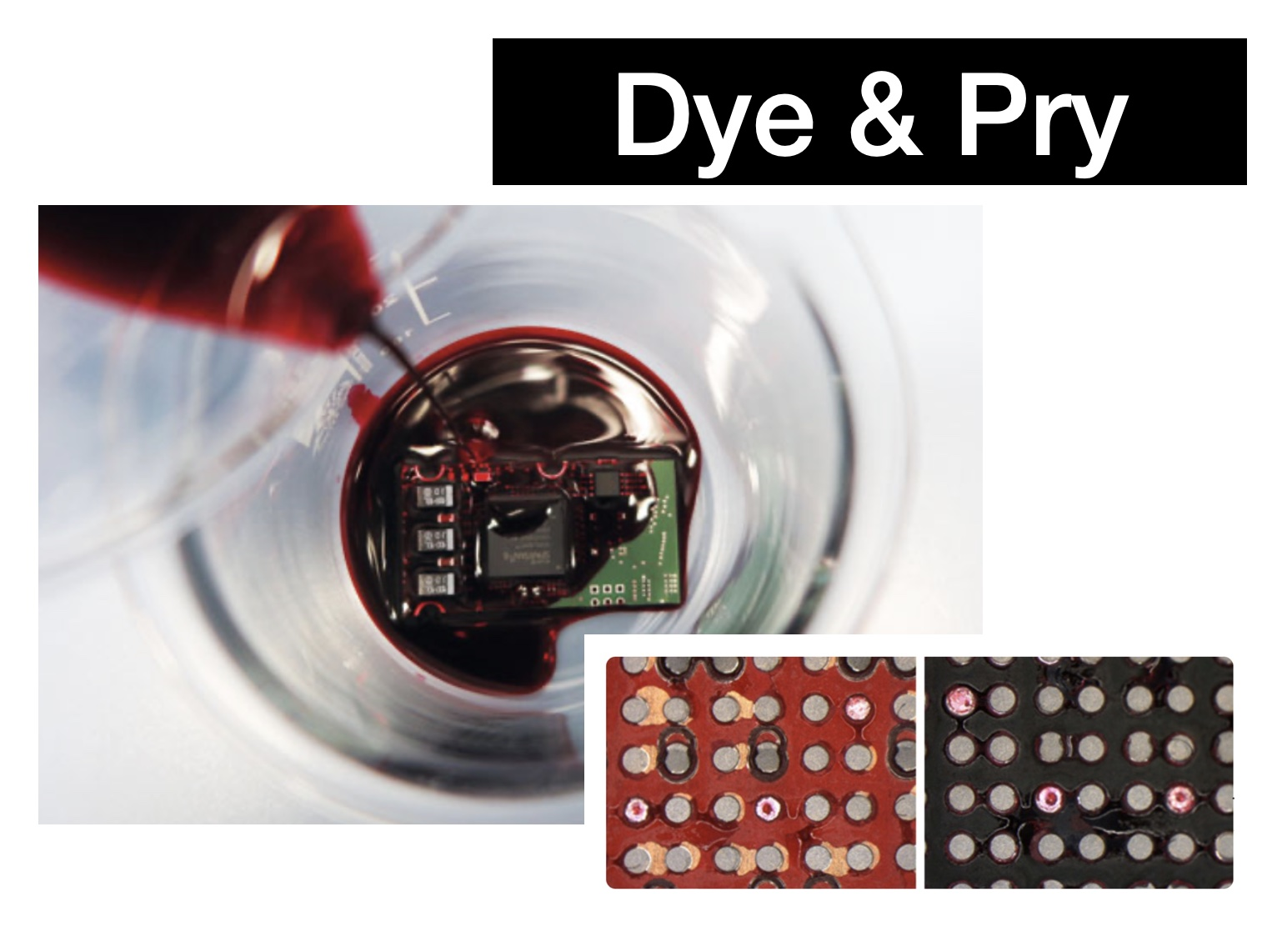

Dye & Pry

Submerge a speciment in red ink/dye for a period(let dye penetrate all area), then dry it and proceed separation, inspect the presence of dye around interconnecting area. Used to detect if interconnect cracked/lifted.

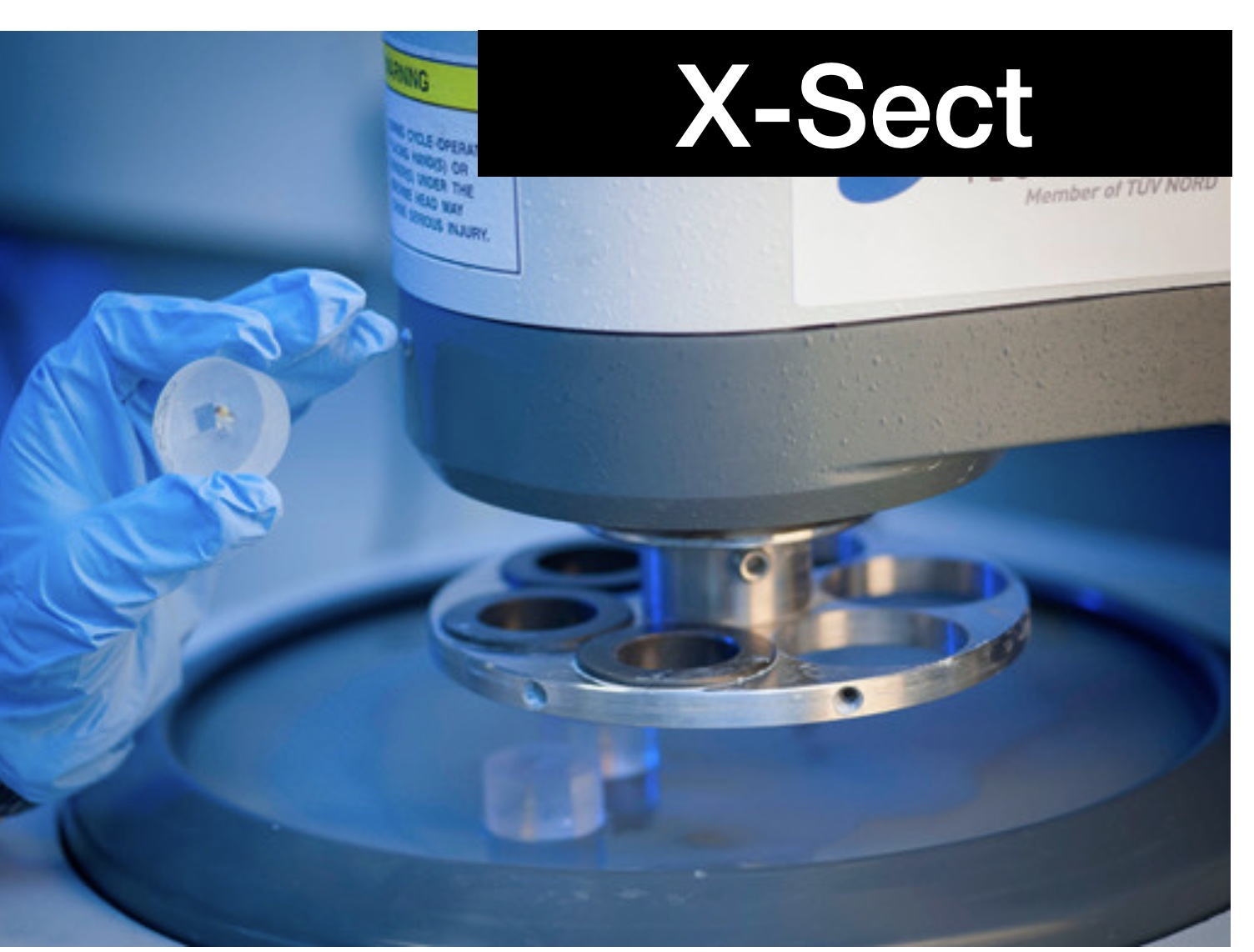

Cross Section

Place a speciment in potting cup, pour in resin until full, vacuum, dry, grinding. Microscope/SEM to examine the mechnical defect or structure of the layer.

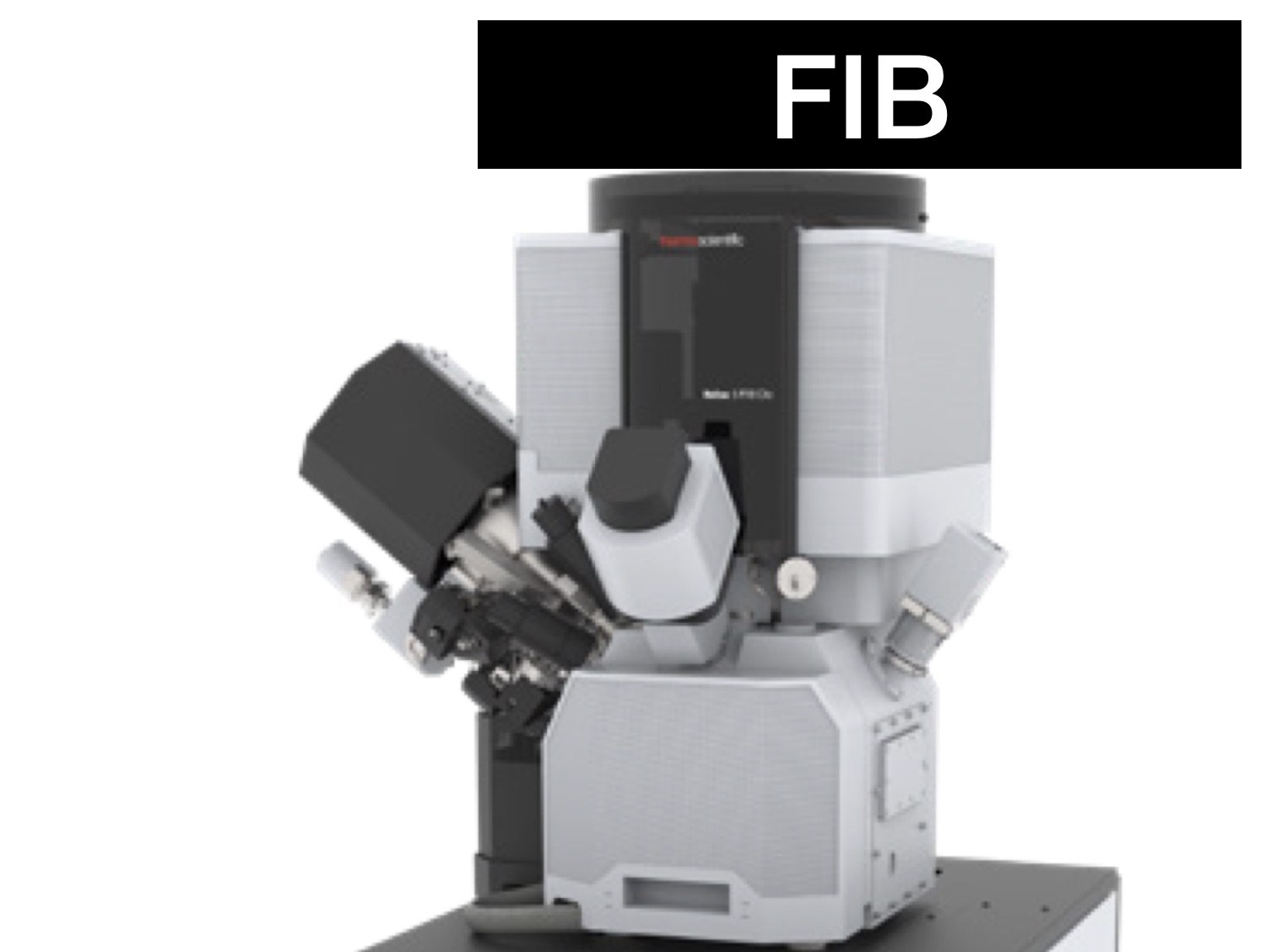

Focus ION Beam (FIB)

Using ion beam to mill the specimen in fine rate, while imaging the newly exposed surface using an electron beam(SEM). Objective same as X-sect, but without any mechanical stress applied and no debris from grinding that impact the imaging step.